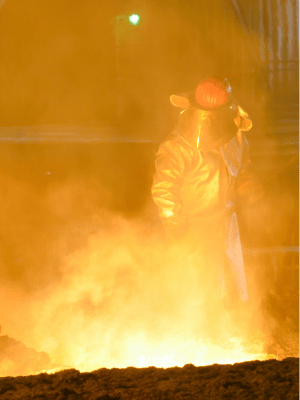

Dust control is a critical aspect of any manufacturing industry, dust control in the steel mills is no exception. Not only does effective dust control protect operators from harmful dust, but it also prevents explosions, reduces housekeeping tasks, minimizes breakdowns, and improves product quality by preventing cross-contamination. With the objective of addressing this challenge, Air Cleaning Blowers is dedicated to providing a unique and effective dust control solution.

Protecting Operators

The well-being of employees should always be a top priority for any business. In the steel industry, prolonged exposure to welding fumes and the dust generated during processing can pose serious health risks. For example, the toxicity of nickel metal and inorganic nickel compounds can cause skin irritation, eye irritation, allergic reactions, inflammation of the lungs, and even cancer. Similarly, exposure to silica dust can lead to severe skin conditions and damage to the lungs and airways.

In order to comply with the legal obligations under COSHH (Control of Substances Hazardous to Health), it is crucial to implement effective dust control measures. By minimizing dust emissions and ensuring proper ventilation systems, companies can protect their workforce from respiratory illnesses, skin reactions, and other adverse health effects.

Minimizing Cross-Contamination

In addition to protecting operators, dust control in the steel industry also plays a crucial role in preventing cross-contamination. The production of different steel products often involves handling various materials with high value. This means that there is a need to reclaim the filtered product and avoid any contamination that could render the end product unusable.

By using an Air Cleaning Blower, companies can minimize the risk of cross-contamination. This not only ensures the quality and safety of the final product but also maximizes product yield and profitability. With proper dust control measures in place, steel manufacturers can maintain a high level of product integrity and avoid costly wastage.

Reduce Housekeeping and Minimize Breakdowns

Dust emissions have a significant impact on the overall production environment. Using an Air Cleaning Blower to control dust at its source can prevent machinery from getting clogged, thus reducing the risk of breakdowns, and minimizing costly maintenance requirements. As a result, productivity improves, and money is saved by reducing the need for operator intervention. Additionally, traditional air filtration systems themselves often become clogged. However, our Air Cleaning Blower does not require media filters, which means it will never clog and eliminates the expenses associated with periodically replacing filter elements and the maintenance involved in traditional air filtration systems.

In addition, when dust is not controlled at its source, it tends to spread throughout the facility, leading to increased housekeeping tasks. Regular cleaning becomes necessary to maintain a clean and safe working environment for employees. By utilizing an Air Cleaning Blower, companies can effectively prevent dust from entering the production environment. This significantly reduces the need for extensive housekeeping tasks.

Dust control is a crucial aspect of the steel industry, offering numerous benefits for both operators and the production process. By implementing an Air Cleaning Blower, companies can protect their workforce from harmful dust, prevent explosions, reduce housekeeping tasks, minimize breakdowns, and improve product quality by preventing cross-contamination.

Investing in proper dust control measures not only ensures the well-being of employees but also contributes to a more efficient and profitable operation. With an Air Cleaning Blower in place, steel manufacturers can create a safer working environment, minimize wastage, and deliver high-quality products to their customers. Dust control should, therefore, be a top priority for any company operating in the steel industry.

For more information contact Amber at amurphy@aircleaningblowers.com