REMOVING UNWANTED PARTICLES

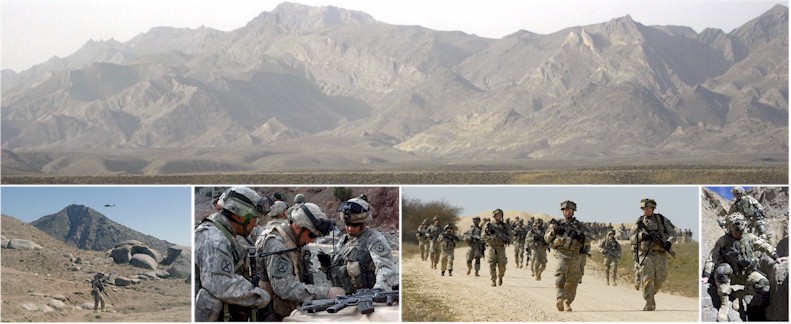

- Operating a dining area or kitchen in a military camp, whether in the desert, jungle, or elsewhere, presents inevitable challenges with dust, flying bugs, and other airborne particles. Ventilation, whether through doors, windows, or other means, often introduces unwanted contaminants like dust and sand. Effectively controlling these particles is crucial for maintaining a clean and safe environment in such settings.

- The Air Cleaning BlowerTM (ACB) offers a tailored solution to this problem. Specifically designed to operate in dusty and harsh environments, the ACB efficiently removes dust, pollen, and other particles from the air without the need for filter maintenance due to clogging. By eliminating the reliance on filter elements or media, our ACBs ensure the delivery of clean air to your dining or cooking facility, even in challenging military environments.

TRAVELS WELL WITH TROOPS

- The portability and adaptability of Air Cleaning Blowers (ACBs) make them ideal for expeditionary activities. They are rugged, lightweight, self-contained, and easily transportable, mountable, and removable by one person without specialized training. ACBs can be configured to operate on various types of electricity, including direct current from vehicles, ensuring versatility in deployment scenarios.

- Additionally, ACBs are effective at removing rain, mist, and snow from the air, contributing to dryer air conditions and reducing the strain on air conditioning, refrigeration, or dehumidifying equipment. Since ACBs don’t utilize filter media to capture precipitation, there’s no risk of components becoming wet or frozen, ensuring uninterrupted airflow and functionality.

COMMON APPLICATIONS

Removing dust and particles from the air to keep tables and food clean

Keeping mist and humidity out of the air

Remove dust and particles form the air for military personnel to breathe more easily

Eliminating the need for replacement filters in in-hard-to-supply locations

Reducing the size and weight of filtration systems

Incorporating them into ECUs (environmental control units)

Keeping flying insects out while ventilating, particularly in temporary structures where ECUs are not an option

HOW AIR CLEANING BLOWERS WORK

- The Air Cleaning Blowers operate by drawing in dirty air into their housings, a process similar to other fans. The impeller and housing are uniquely engineered to leverage the momentum of contaminants, separating them from the air or gas. These contaminants are then expelled toward the outside of the housing, while the clean air continues its path toward the intended application. Notably, ACBs achieve this without the need for any filter elements, sheets, cartridges, bags, or other media, simplifying maintenance requirements.

- Media filters function by capturing contaminants from air and gases, leading to eventual clogging and requiring maintenance or replacement. As they become clogged, they impede airflow, forcing the blower to work harder and consume more energy to maintain consistent airflow and pressure. However, Air Cleaning Blowers (ACBs) operate differently. Since they don’t trap debris, they don’t clog, significantly reducing the need for maintenance and eliminating deferred maintenance.

- Additionally, by integrating air movement and cleaning functions, ACBs mitigate fluctuations in airflow, pressure, and power consumption, simplifying the prediction and calculation of air system performance and facilitating the design of optimal systems.

PRESSURIZING AIR

- The ability of ACBs to pressurize spaces is valuable in preventing the ingress of dust and sand, particularly in challenging environments. Moreover, this pressure can aid in directing cooking smoke and grease up vents without the need for additional fans, simplifying maintenance and cleaning efforts

- ACBs have undergone rigorous independent testing, demonstrating their effectiveness in removing a significant portion of dust and particles from the air. This ensures cleaner air quality, especially important in food preparation areas where contaminants can compromise hygiene standards.

- Originally developed for harsh industrial settings, ACBs are versatile enough to be deployed in various kitchen and dining environments, regardless of location or operating conditions. Their effectiveness has been proven in demanding environments, including deployment by the US Military in the Middle East to maintain cooling systems amidst sandstorms.